- Browse Categories

- FLEXIBILITY TILE GROUT

- WATERBORNE TILE GROUT

- POLYUREA TILE GROUT

- WATERBORNE EPOXY ADHESIVE

- EPOXY TILE JOINTS ADHESIVE

- MILDEW PROOF SEALANT

- Certifications

-

- Subscribe

-

Get email updates on new products

- INDUSTRY INFORMATION

- Follow us

POLYUREA TILE GROUT TPG01

- Polyurea- which widely used in military industry

- No yellowing and discoloration, even outdoor used

- Imported better raw materials

- Cosmetic grade dye, Vivid colors

- Can be constructed on wet base

- Fast curing, Same-day finish construction

- Same service life with tiles

- Better mouldproof & moistureproof

- Environmental & Non-poisonous

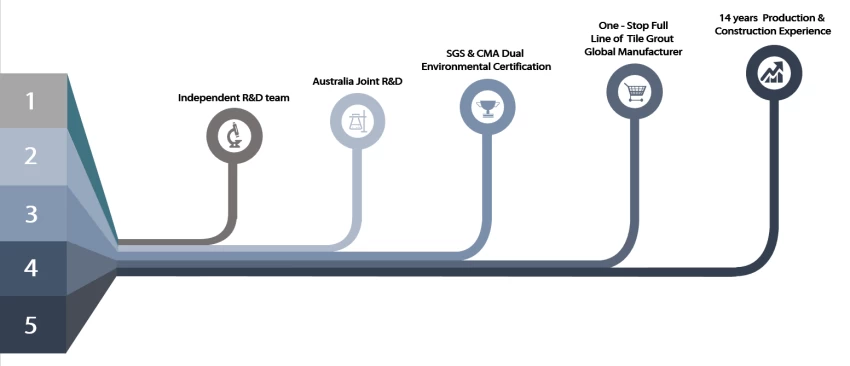

Kelin polyurea tile grout is a new overturning product. And we are also a China flexible tile grout factory. Due to POLYUREA’s excellent wear-resistance, corrosion-resistance, yellow-resistance, high temperature resistance and other superior performance, it is widely used in the military industry, aerospace and vessels industry. In addition, it solidifies quickly, construction and clean edge in the same day, save time and labor costs. More importantly, it can be constructed in wet subbase surface, which greatly solves the problem that cannot construct because of climate and other reasons. Australia joint research and development products to make the better performance, and through the Chinese Academy of Sciences strategic quality control guidance, to make products' quality stable.

| Main Ingredient | Polyurea, High-end color powder |

| Function | The filling and beautification of tile gap |

| Shelf Life | Stock in a cool and dry place at 0-37 ℃ for 8 months |

| Net Weight | 450 ML |

| Packing | 30 Sets/Carton |

Our product is totally polyure basic product, can be better used in the joints of ceramic tile, stone, glass, mosaic tile on the wall or flour indoor & outdoor. It has its own special characteristics: permanent moisture proof, more environmental, curing fast, save labor and never discolor, which is its biggest advantage. China epoxy gap filler factory will be your best choice for your decoration.

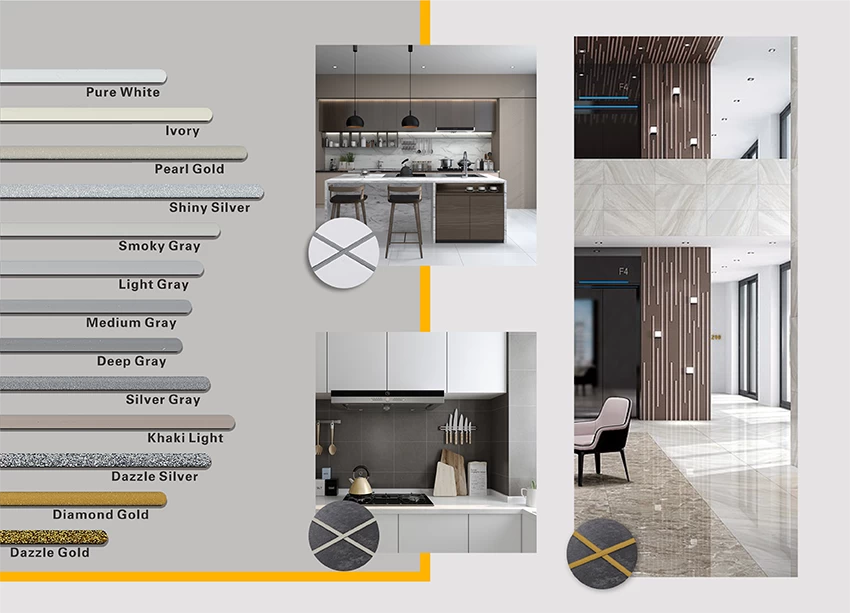

Varieties of colors for your choice. Also provide custom colors.

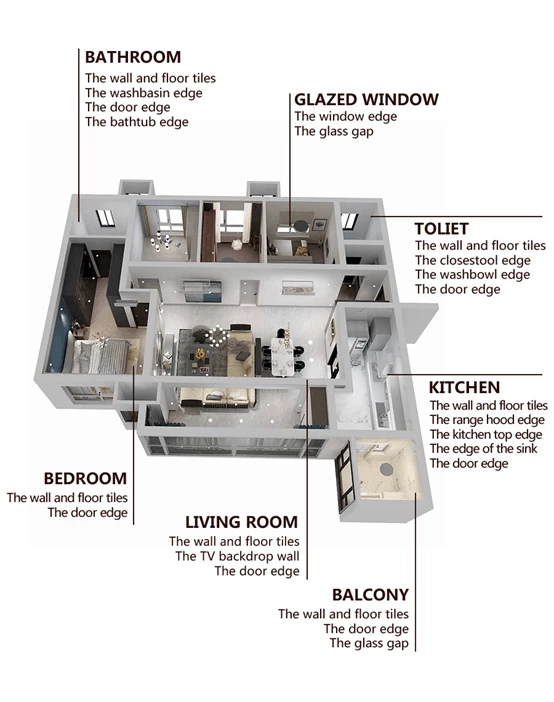

Provide Whole Room Gap Solution

Brief Construction Process

|

|

|

|

|

|

Clean the tiles and keep it dry.

|

Polish with tile wax except the glazed tile.

|

Open & Watch, both sides can extruded meanwhile.

|

Screw on the nozzle, put on the grout gun.

|

Inclined cut the top of the nozzle in 45°.

|

|

|

|

|

|

|

Squeeze out 60-80cm long grout in the forepart. |

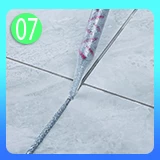

Evenly squeeze out the tile agent along the gap. |

Press the grout with professional glue-press tools. |

Don't touch in 2-4 hours and remove excess grout then. |

Keep the tiles dry in 24 hours. |

Professional Joint-Pressing Tool

Company Advantage

Factory Overview

|

|

|

|

|

| Creaming Machine Line | Testing Machine | Batching Production Line | Cooling Filing |

|

|

|

|

|

| Filling Machine Line | Film-coated Machine | Real Material Stock | Stock |

Certification

+86 15140071761

+86 15140071761 sales@tilegrout.net

sales@tilegrout.net